Label Converting Machines and Label Finishing Machines

-

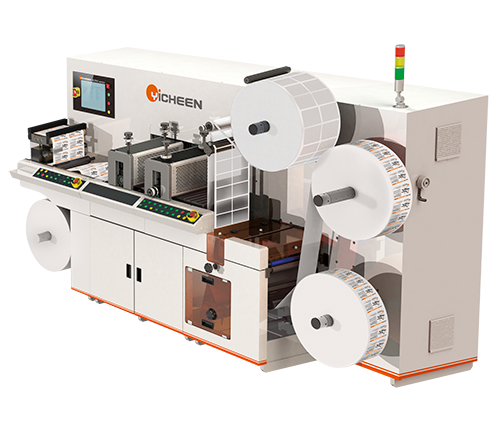

EPC

-

Laminating

-

Die Cutting (Front & Back Die Cut)

-

Liner Razor

-

Varnishing

-

Slitting/Cutting Sheet

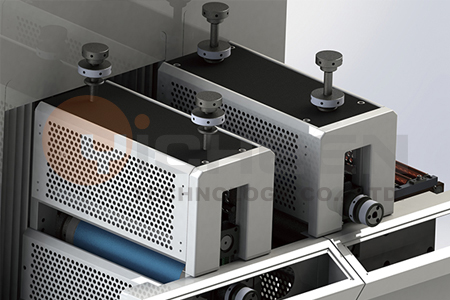

Optional Mechanism:

EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet

Application:

IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material…etc

Label Converting Machines and Label Finishing Machines

We offer a wide range of Label Converting Machines and Label Finishing Machines for plain label production. The label converting process is an important part of label manufacturing. The final stage in the production process consists of a number of processes that take place after printing. All with an essential role to play in producing the final labels. Each operation is supported by specialized label converting equipment, which is sometimes used independently, or as modules as part of a larger printing plant.

Read more : The Importance of Label Converting - Die Cutting Machines

Description:

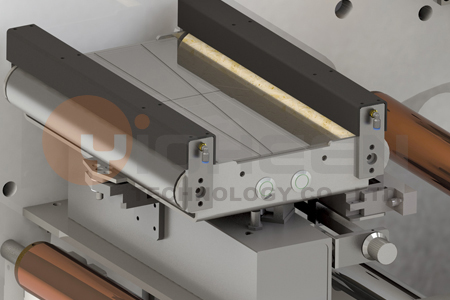

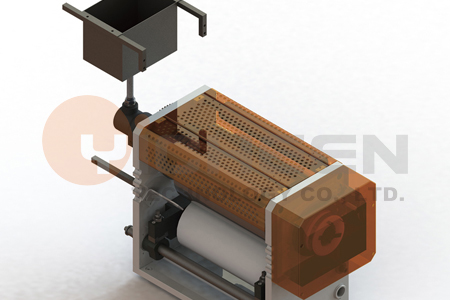

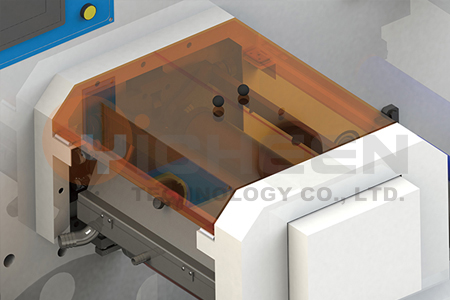

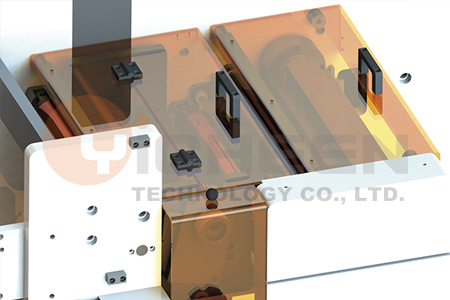

- Running operated by full rotary die cut method or intermittent die cut method.

- Die is easy in change, save a lot of time in die mold adjustment.

- Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession.

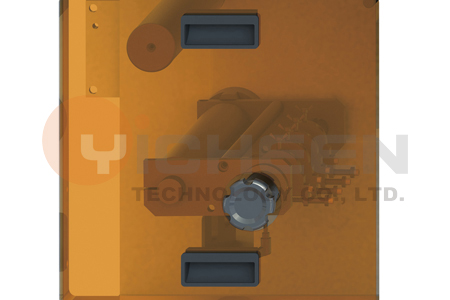

- Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control.

- Sensor detector and alert for broken material to reduce material lost.

- Optional module for satisfying customized demands.

SPECIFICATIONS

| Model | RD-340 |

| Intermittent rotary die cut speed (max.) | 300cycle/min(+/-60m/min) |

| Full rotary die cut speed (max.) | 100 m/min |

| Die cut precision | ±0.15mm |

| Label die cut precision | ±0.25mm |

| Max. die cut size | L380mm x W350mm |

| Material width | 10mm-350mm |

| Unwind dia. (max.) | 700mm |

| Rewind dia. (max.) | 700mm |

| Standard magnetic cylinder | 120 gear tooth |

| Repeat die cut length | 20mm-250mm |

Specifications are subject to change without notice for design improvement.

The specification can be designed by customers demand.